-

SOLIDWORKS FLOW SIMULATION

SOLIDWORKS® Flow Simulation is an intuitive Computational Fluid Dynamics (CFD) solution embedded within SOLIDWORKS 3D CAD that enables you to quickly and easily simulate liquid and gas flows through and around your designs to calculate product performance and capabilities.

Why Choose FLOW SIMULATION?

SOLIDWORKS® Plastics delivers easy-to-use simulation for analyzing plastic parts and injection molds. It simulates how melted plastic flows during the injection molding process to predict manufacturing-related defects so you can quickly evaluate part manufacturability while you design.

STANDARD

SOLIDWORKS Flow Simulation is a general Parametric flow simulation tool that uses the Finite Volume Method(FVM) to calculate product performance through “what if” studies that allow you to perform optimization using the result.

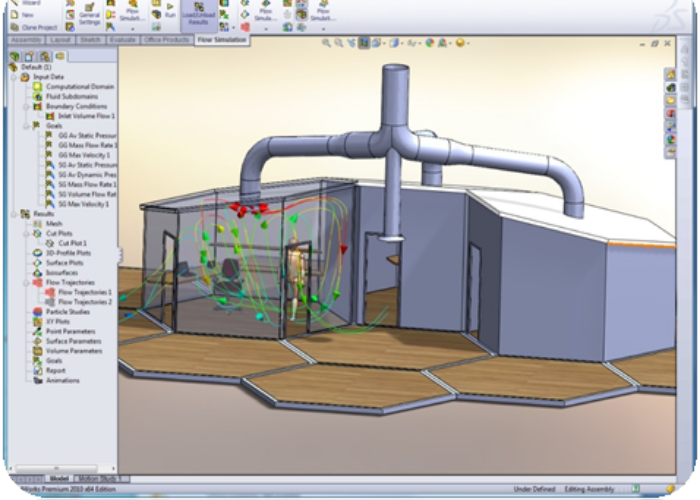

HVAC Module

Dedicate heating, cooling and ventilation tools for simulation HVAC systems and radiation phenomena

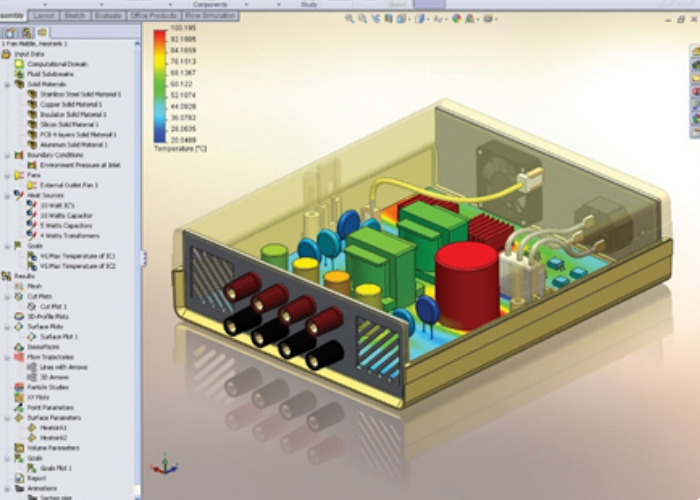

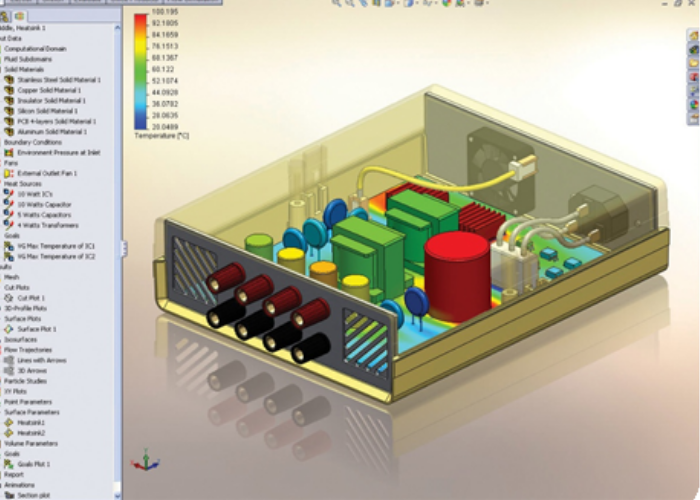

Electronics Cooling Module

Dedicated thermal management study simulation tools for accurate thermal analysis of electronic printed Circuit Board(PCB) and enclosure designs.

SOLIDWORKS Flow Simulation Tools

FEA Integration

System-level design requires optimizing fluid behavior and material strength. Because SOLIDWORKS incorporates CFD analysis and FEA, designers can incorporate both with the FEA transfer from SOLIDWORKS Flow Simulation. This allows engineers to use the resulting force and heat transfer effects from their CFD analysis as the load inputs in their FEA analysis to fully understand the structural behavior based on fluid behavior

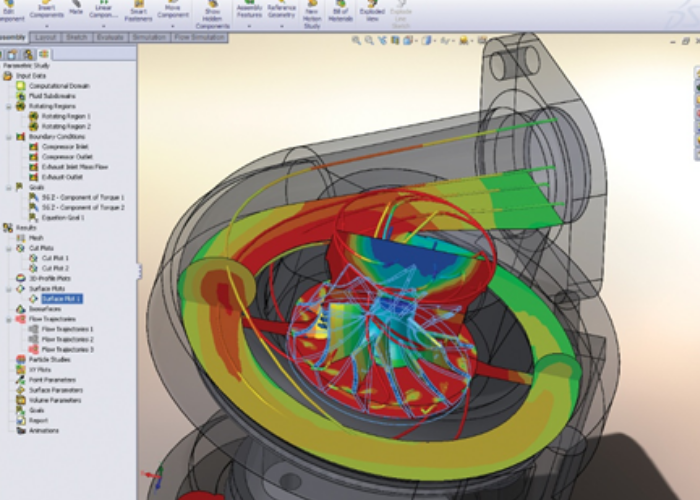

Rotating System Analysis

Coming up with optimal designs for systems with fan blades or impellers is impossible without accurate results. SOLIDWORKS Flow Simulation provides users with tools that allow for rotating regions and sliding mesh methods to accurately simulate the behavior of these types of systems based on geometry, angular velocity, and transient behavior of the fluid.

External Flow Analysis

External analysis is used when we need to understand the fluid behavior around our model based on the environmental conditions. Wind turbines, airplanes, ships, heat sinks, and automobiles would all be studied using external flow analysis. In external studies, the computational domain acts as our virtual wind tunnel with boundary conditions, heat sources, and transient behavior all applied through the user-friendly setup wizard.

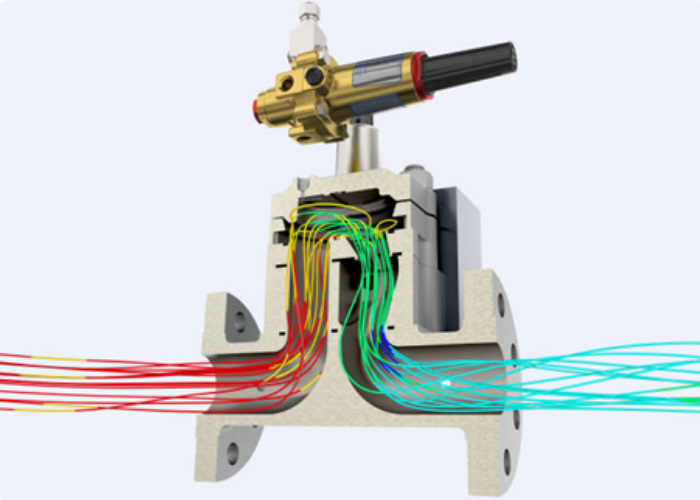

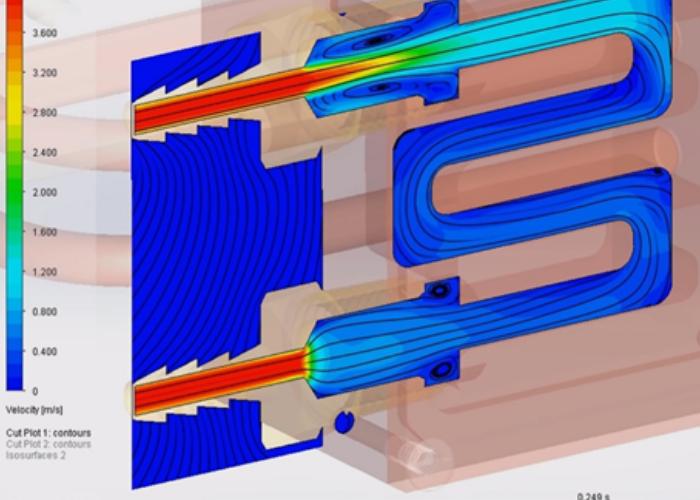

Internal Flow Analysis

PCB enclosures, valves, pumps, and manifolds are all examples of internal analysis studies. Because SOLIDWORKS Flow Simulation functions inside of SOLIDWORKS, setting up computational domains, boundary conditions, and heat sources can be done in minutes. The results of your analysis can be applied directly to your design allowing you to test more iterations in less time.

Free Surface Dynamics

Free surface is a condition with a freely moving surface between two fluids that don’t mix, such as air and water. Using the Volume of Fluids approach, we can accurately simulate transient conditions such as tank sloshing or any open bath fluid behavior. Not only can these tests give us a better understanding of what the fluid is doing in the system, but we can also gather useful quantitative results such as force or pressure on internal walls.

Electronics Cooling Module

An add-on for SOLIDWORKS Flow Simulation, the Electronics Cooling Module (ECM) provides additional materials and material models that are specific to circuit board and PCB enclosure analysis. The Two-Resistor component model is a JEDEC approved method for simulating chip temperatures such as BGA, QFP, QFN, and SOP. The PCB-generator understands layer properties to provide accurate orthotropic thermal behavior. Joule heating capabilities mean designers can apply current as the input to estimate heat generation.

HVAC Module

Accurately understanding HVAC systems is a complicated task. That’s why SOLIDWORKS created the HVAC add-on module for SOLIDWORKS Flow Simulation. This tool provides additional capabilities such as advanced radiation which modifies the way radiation between bodies, including semi-transparent materials such as glass, is calculated to provide higher fidelity of result information. The tracer study function allows the simulation of pollutants in a volume and shows how and where that pollutant will disperse in an environment.

Which package is right for you?

| SOLIDWORKS Flow Simulation | HVAC Module | Electronics Cooling Module | ||||

| Ease of Use | ||||||

| Design Data Reuse | ||||||

| Multi-Parameter Optimization | ||||||

| SOLIDWORKS Flow Simulation Capabilities | ||||||

| Material Database | ||||||

| Internal | ||||||

| External | ||||||

| 2D – 3D | ||||||

| Heat Conduction in Solids | ||||||

| Gravity | ||||||

| Rotation | ||||||

| Free Surface | ||||||

| Summetric | ||||||

| Gases | ||||||

| Liquids | ||||||

| Steam | ||||||

| Boundary Layer Description | ||||||

| Mixing Flows | ||||||

| Non Newtonian Fluids | ||||||

| Flow Conditions | ||||||

| Thermal Conditions | ||||||

| Wall Conditions | ||||||

| Porous Components | ||||||

| Visualization | ||||||

| Results Customization | ||||||

| Communication & Reporting | ||||||

| Two-phase (Fluid + Particles) Flows | ||||||

| Noise Prediction (Steady State and Transient) | ||||||

| HVAC Conditions | ||||||

| Tracer Study | ||||||

| Comfort Parameters | ||||||

| Electronic Conditions | ||||||